CONTINUOUS CROSSING TECHNOLOGY FOR CHROME PLATING PLANTS

When producing mechanical parts for tough uses, it is custom to protect their surfaces by a galvanic chrome layer.

Many mechanical parts, such as cylinder rods, mechanical guides, presses columns, etc..., can be easily and economically produced

by machining a chrome plated bar, instead of plating the parts at the end of the production process.

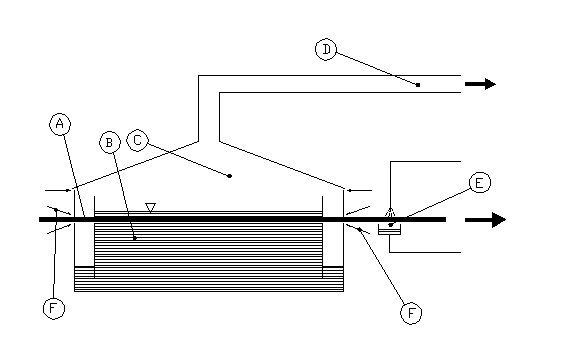

Chrome plating

Chrome plating is an electrochemical process used to cover a metal surface with a chrome layer, by dipping it into a tank containing

chrome acid solution and connecting it to the negative pole of a current rectifier, while the positive pole is connected to anodes, dipped in the same tank.

A Current rectifier

B Chrome solution

C Plating part

D Anode

Rods are long cylindrical shapes whose diameter is very small compared to the length.

Chrome layer thickness is usually between 10 and 50 microns.

Before plating, the steel surface must be finished at a very fine roughness, because the chrome layer quality is affected by the steel

surface existing before plating.

After plating, the chrome surface must be polished to improve the roughness and to remove the chrome layer tensions.

These two steps are very important to get a high corrosion resistance

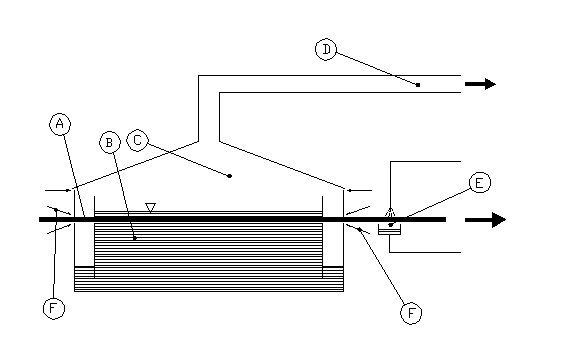

TRADITIONAL PLATING BY DIPPING

Historically, plating technology consists in fixing the rods on a frame and dipping it into the tank.

The frame is connected to the negative pole of a current rectifier, whilst in the tank there are lead anodes electrically connected to the positive pole.

This traditional rod plating process faces some problems with pollution, quality and energy

For commercial rods longer than 6 meters, the tanks length causes a broad upper surface. This produces a lot of fumes, increased by the bath solution temperature.

A Chrome bath solution fumes

B Plating rods

C Frame

D Chromic acid bath solution

E Rectified current generator

When picking up the rods from the bath, chrome solution drops on the ground; expensive equipment must be used to solve it.

Big tanks are filled by many thousand litres of chrome bath solution and, all over the world, the laws for dealing with chrome acid are very strict for the industries.

Big tanks, open on the top, are difficult to close in a sealed system to avoid environmental pollution and to protect from accidents

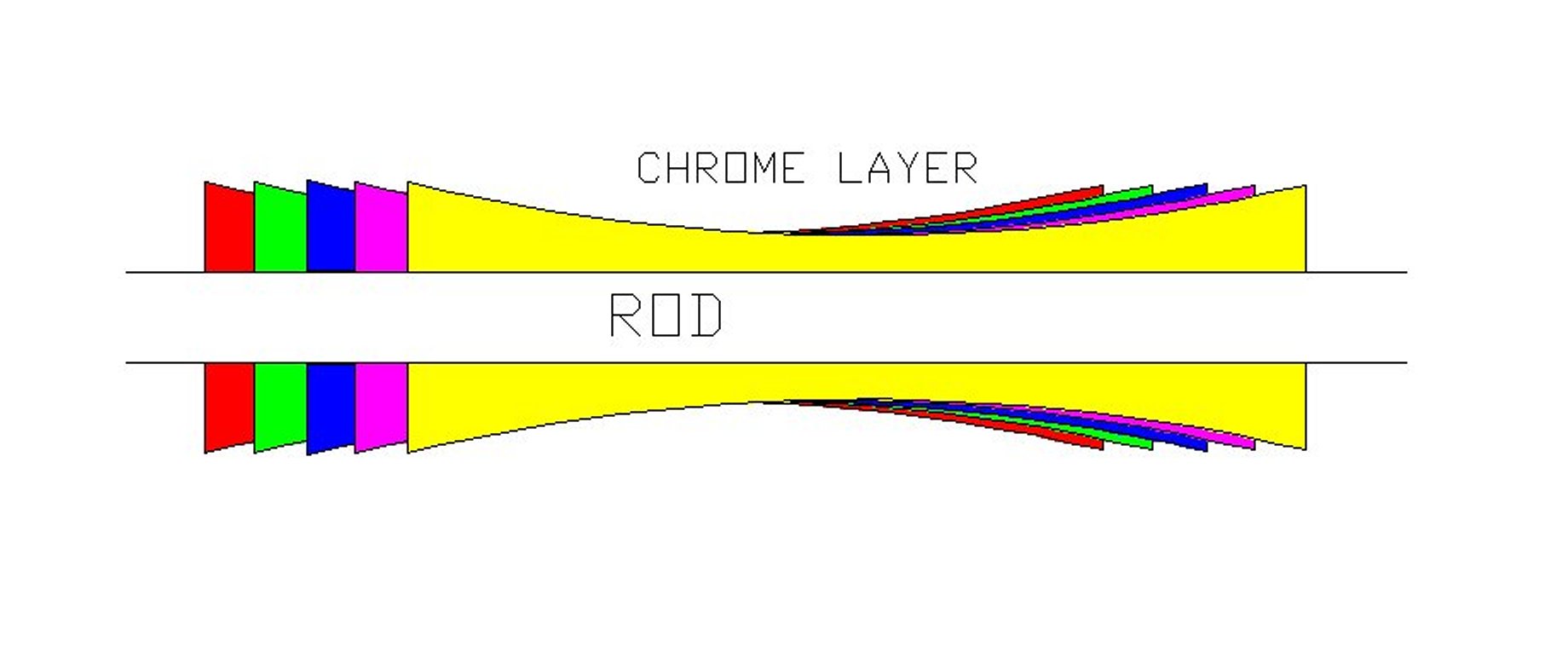

The position of the anodes is radially asymmetric to the rods, so that the chrome layer isn’t constant.

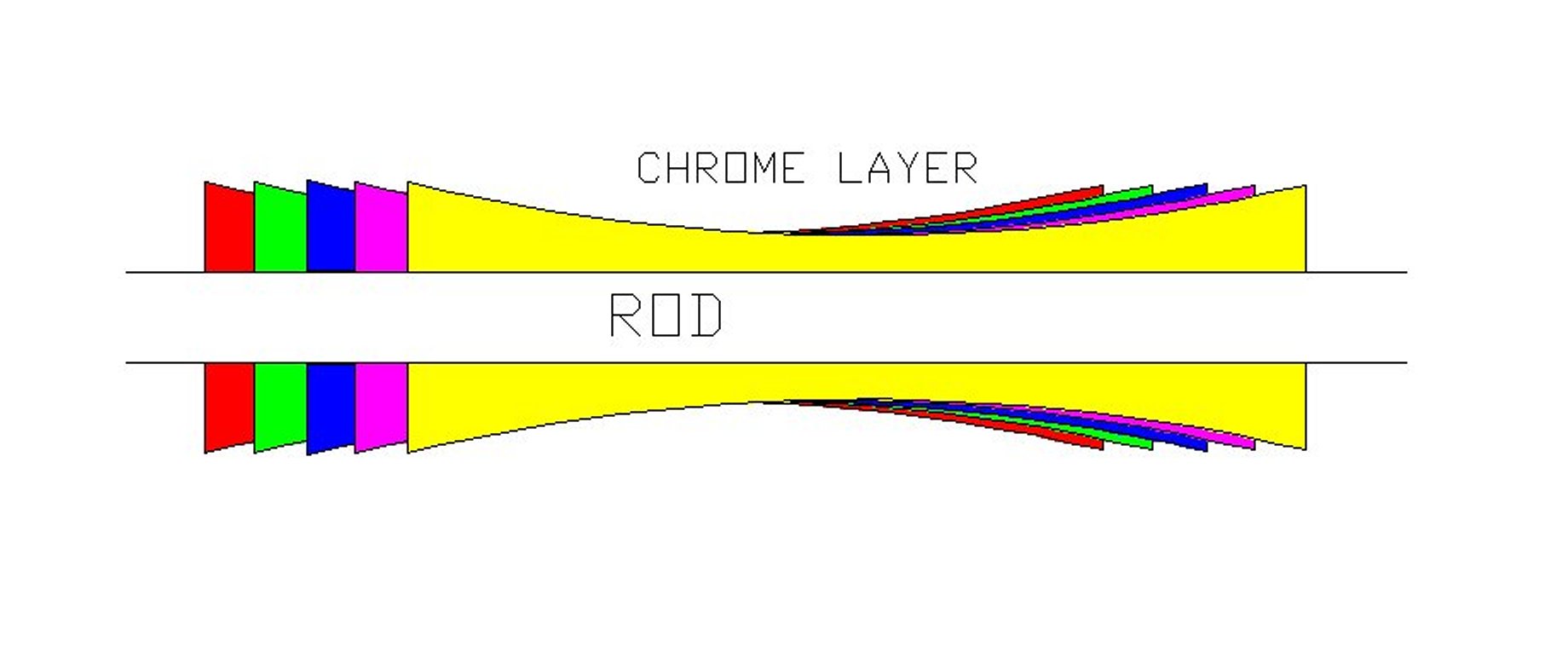

|

A Anodes A Rod

B Rod B Chrome layer

C Anodes

|

|

Electric current connected to the ends of long rods, causes a resistance which affects the chrome layer thickness in its axial direction, too.

A Electric supply

B Rod

C Chrome layer

D Anode

Beside the quality level, there is one more problem facing the old technology.

Modern industry needs high quality constancy.

The technological characteristics of the production must be very similar; to achieve this, the production equipment must be at a very high automation level, to not

depend on workers cleverness and attention.

The old technology could also be automatic, but at huge cost.

The contact at the rod ends causes a real scrap and the electrical resistance across the whole length of the rod is a limit to its length.

Dipping rods requires big distance between rods and anodes, causing poor electrical efficiency.

The traditional process produces a poor quality, using more chrome, more energy and is not environmental friendly.

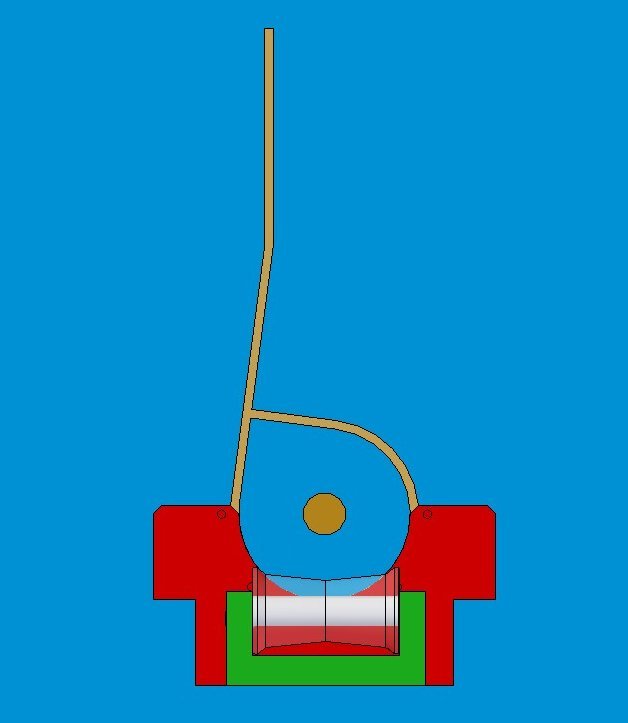

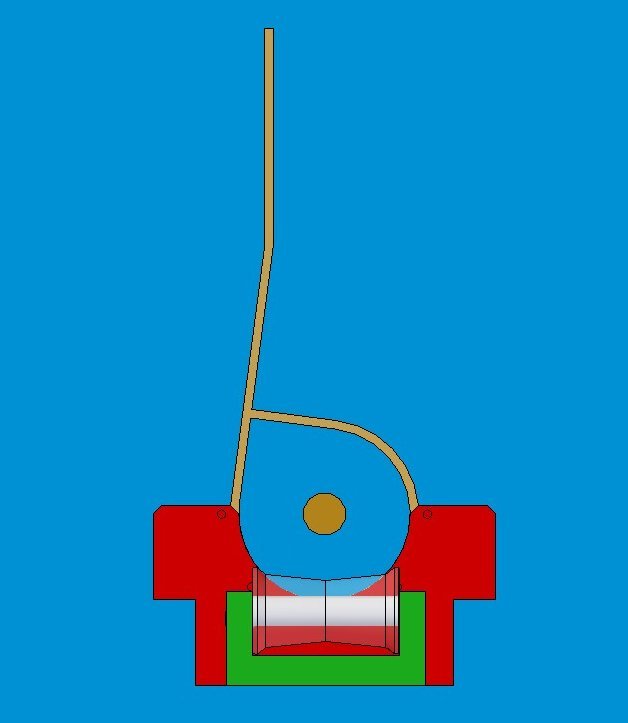

CONTINUOUS CHROME PLATING TECHONOLOGY

Continuous technology avoids or solves all these problems.

Continuous means that the rods enter the tank without stops, edge by edge.

A schematic diagram of the continuous technology is below

Rod A crosses tank B and the plating process affects only a part of the rods.

This reduces the current losses along the rods and its movement produces the same chrome layer thickness over each part of the rod.

Because there is no vertical movement, the system allows cylindrical anodes, very symmetric to the rod.

The small distance between anodes and rod dramatically increases the electrical efficiency of the process

Chrome deposition is constant and precise, even increased by the spinning rod.

The tank is very small and the contained chrome bath solution is many times smaller than in the traditional plants.

The reduced tank area reduces the aerial pollution and it is easily contained in antipollution equipment.

The aspiration put the system at negative pressure; the air can enter the plant but no fumes can exit it.

Reducing fumes reduces their treatment cost

Full sealed plant

Easy automation produces high quality constance and the production is free from workers skillness

Low energy consumption

Low managing cost

No limit in the rod length